Construction

Construction

- Categories:科技创新

- Time of issue:2021-01-12 11:46:01

- Views:0

Industrialization of building

Since the issuance and implementation of the Guiding Opinions of the General Office of the State Council on the Vigor Development of Prefabricated Buildings(Guo Ban Fa[2016]No.71),the industrialization of new buildings represented by prefabricated buildings has been rapidly promoted.In order to fully implement the new development concept and accelerate the industrialization of new construction,the Five Construction Group dared to take the lead,and with the meticulous craftsmanship spirit,found a suitable road for its own construction industrialization.

Since the issuance and implementation of the Guiding Opinions of the General Office of the State Council on the Vigor Development of Prefabricated Buildings(Guo Ban Fa[2016]No.71),the industrialization of new buildings represented by prefabricated buildings has been rapidly promoted.In order to fully implement the new development concept and accelerate the industrialization of new construction,the Five Construction Group dared to take the lead,and with the meticulous craftsmanship spirit,found a suitable road for its own construction industrialization.

Group set up research center of industrialization,and with the country provinces and cities prefabricated construction technical policies and related technical standards as the basis,to implement the fabricated items,PC factory as the platform,around the enterprise production activities of prefabricated building technical problems and key technologies needed to resolve,prefabricated construction in order to improve enterprise technology innovation capability and core competitiveness.

Research field

Main research:prefabricated building design,component manufacturing and transportation,assembly construction,information application and other prefabricated construction technology

1) Prefabricated building design technology:

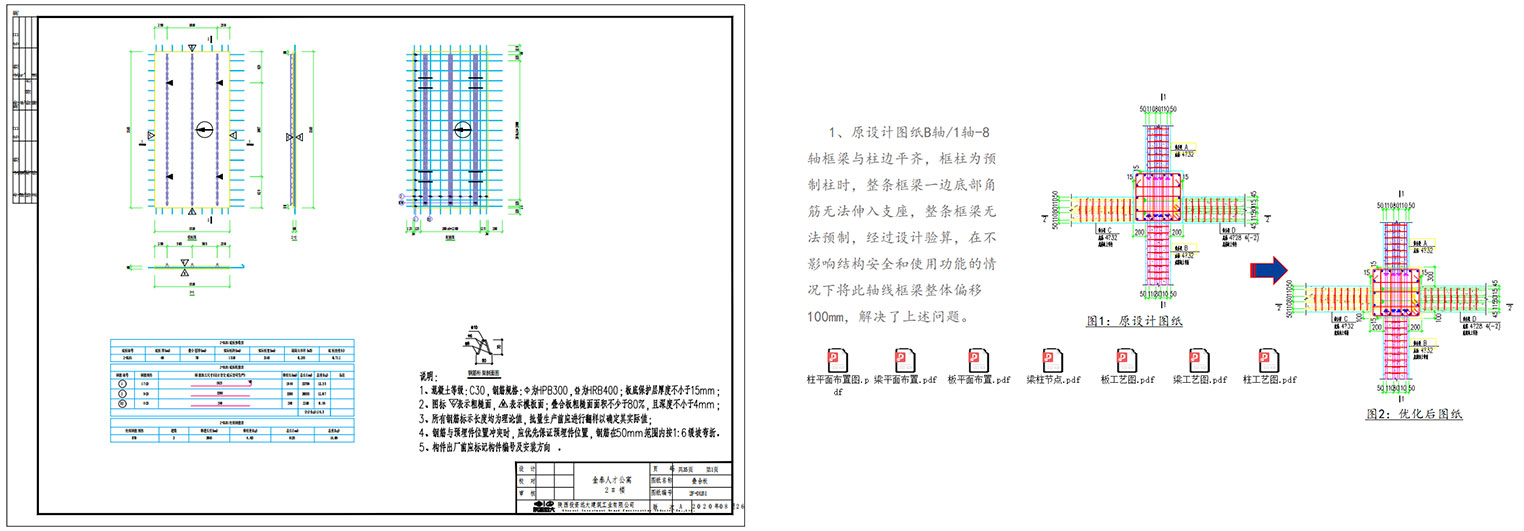

At present,the prefabricated research center can be engaged in industrial workshop,frame structure,shear wall structure,prefabricated decoration design,structure,architectural drawing optimization.

2) Manufacture,transportation and assembly of prefabricated building components

Factory production:

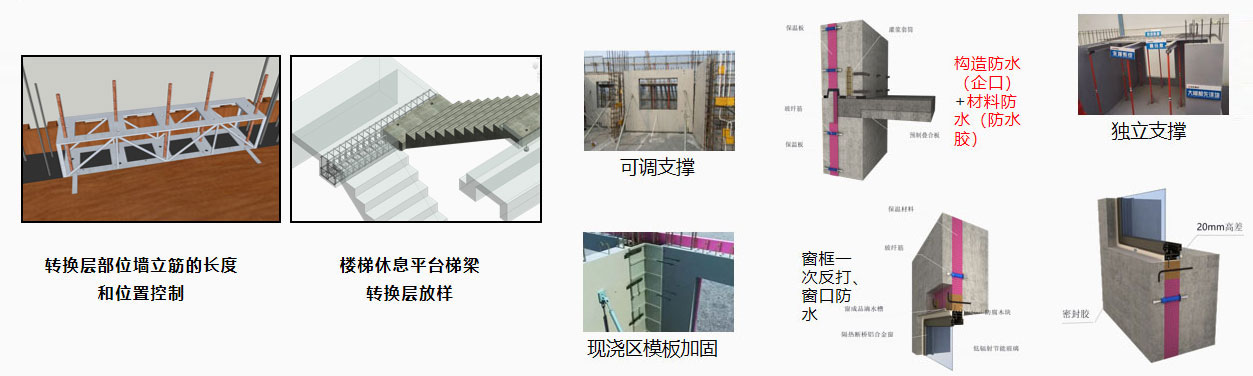

3) Assembly construction:

It has undertaken many prefabricated projects such as industrial workshop,frame structure,shear wall structure and prefabricated decoration design.

4) Information technology application:

Prefabricated construction is the core of"integration",BIM technology is the integration of the main line,in the design,production,construction,decoration and the whole process of management,in the service of design,construction,operations,demolition of whole life cycle,can be virtual,digital information describing various system elements,collaborative design,and visual assembly informatization,New applications,such as the interaction of project quantity information and the simulation and inspection of node connection,integrate the whole construction industry chain and realize the whole process and all-round information integration.

BIM application in assembly-design:

①4D construction simulation

Through 4D progress simulation,combined with lifting analysis of crane station points,the stacking location of components was planned,and the input plan of components was provided to the factory with simulated installation time data.The factory carried out material procurement,component production scheduling and other work in an orderly manner to ensure the needs of on-site installation and supply.After arriving at the site,the components should be unloaded and stowed at the corresponding stacking points to avoid on-site secondary transfer.Video output can provide workers with a visual explanation of the installation process.

② BIM in assembly application-production:

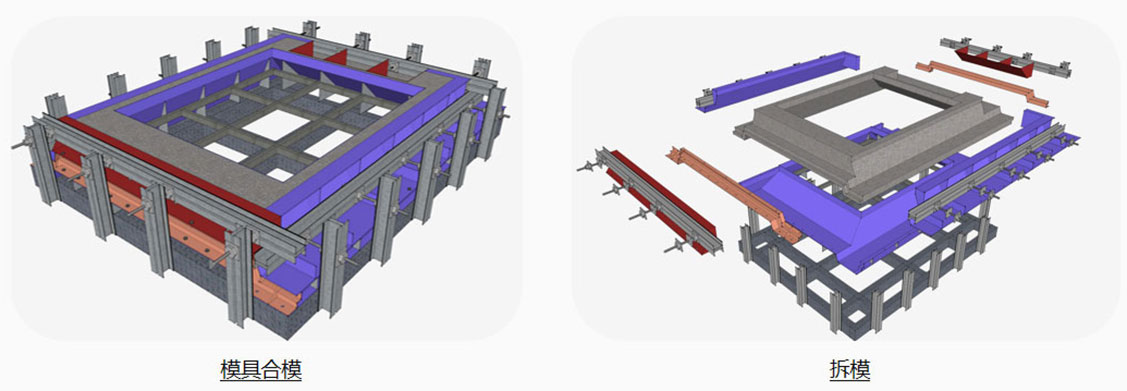

Combined with the type and quantity of components,the details of the components are optimized and adjusted to form the preliminary mold ratio,which creates prerequisites for the cost of project components and the common mold scheme of subsequent components.To avoid the later due to the mold cost amortization is too large and lead to the component design more.

③ BIM application in assembly - construction scheme planning: apply BIM technology to design prefabricated component molds, verify the feasibility of the design component production, and further adjust and optimize the design from the perspective of production.

Construction planning: use BIM technology to simulate according to the construction scheme, confirm the feasibility of the construction scheme, and realize the planning is the implementation.

Detail node practice

Key technology

① Design, manufacture and construction of prefabricated wall hanging board

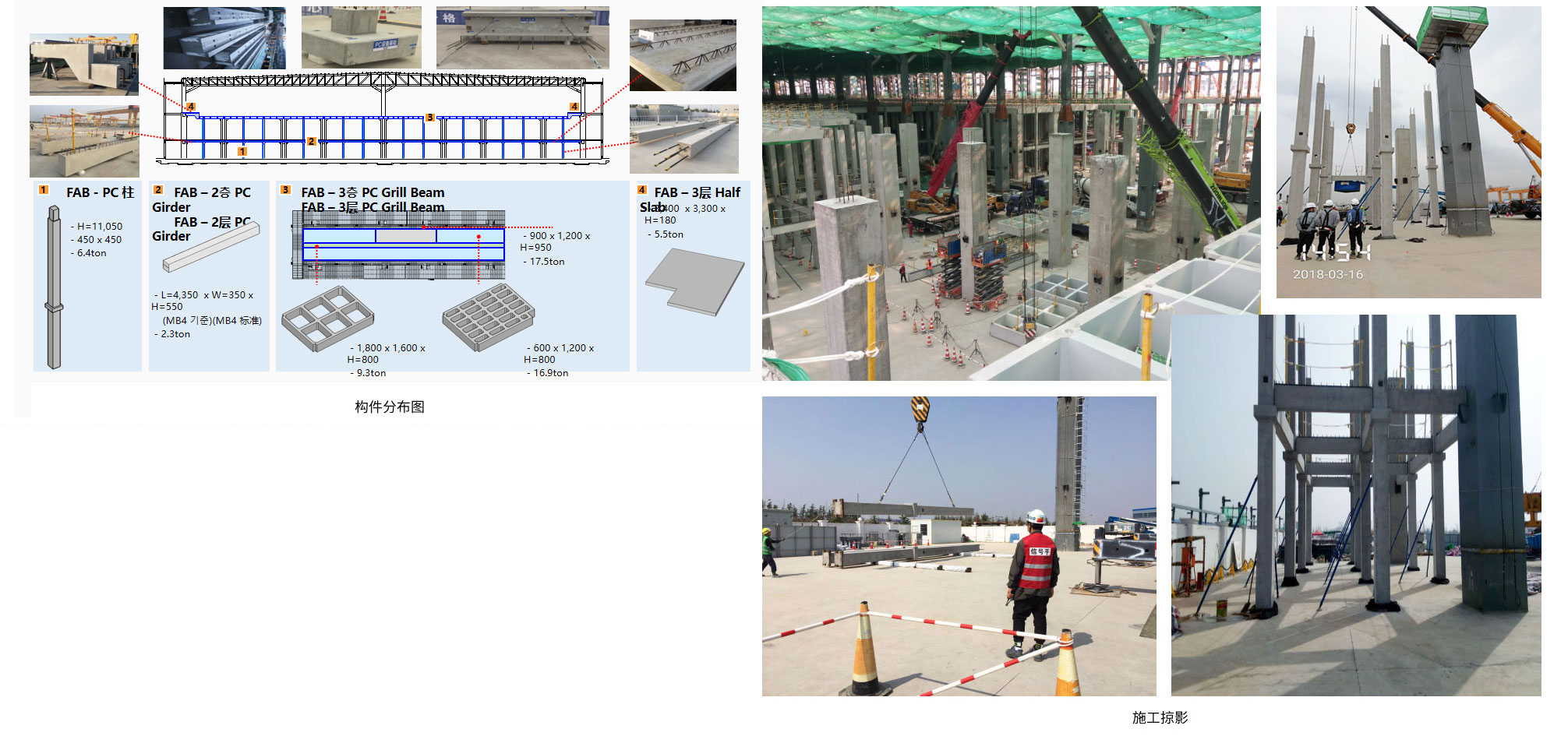

② Construction technology of prefabricated frame structure

PC components include: column + beam + laminated plate; External hanging plate, etc.

③ assembly type decoration technology

Compared with traditional design and construction,assembly decoration is an important part of promoting green building because of unified batch construction,which significantly reduces the cost of industrial decoration and less pollution and waste.

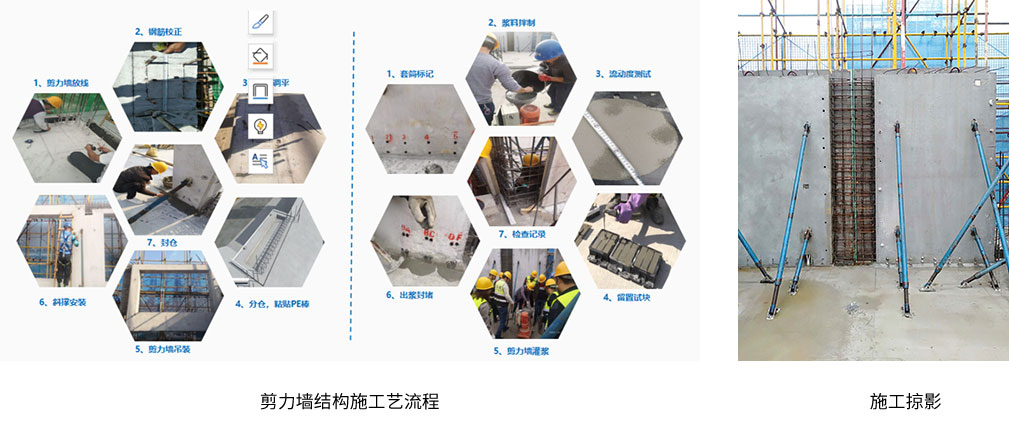

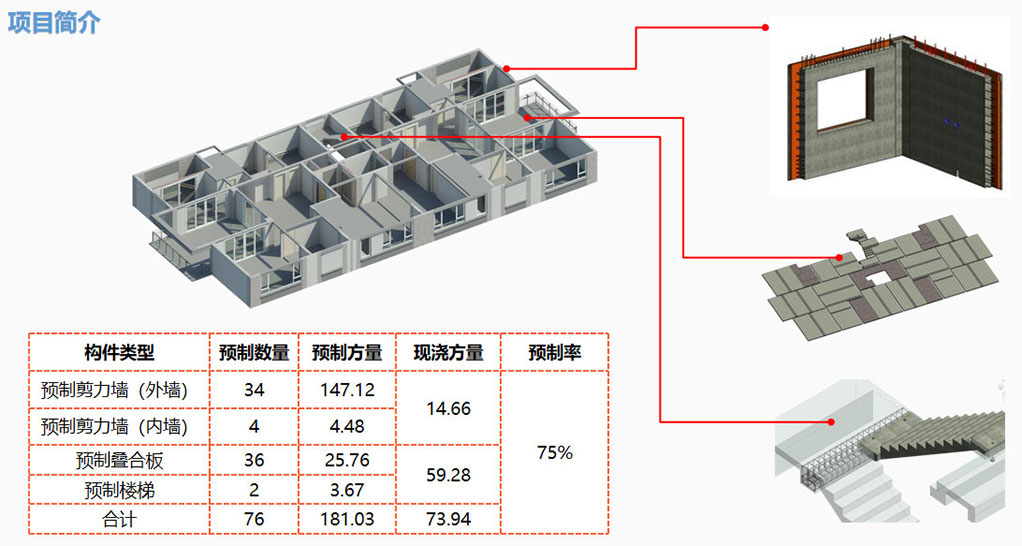

③ construction technology of prefabricated shear wall

PC components include:shear wall(sandwich wall panel)+laminated board;

④ assembly type electronic factory construction technology

Samsung(China)semiconductor 12 inch flash memory chip phase II construction project.This project covers an area of 106,553 square meters,a construction area of 295,122 square meters,a building height of 23.9m,the number of building floors,SRC composite structure.PC engineering includes prefabricated column,single beam,beam,lattice beam,laminated plate,parapet,equipment foundation and other types of prefabricated components,a total of 10,979 times,24319 m³,the heaviest single piece of nearly 19T;

Successful cases

1) The second phase construction project of Samsung(China)semiconductor 12-inch flash memory chip,which is the largest prefabricated electronic factory project in China.

Manufacturing process:--Aduse"fixed membrane technology",divided into A,B,C three production lines,A total of 154 sets of molds,10,392 components,about 20,000 cubic meters,the average turnover 67 times,higher standard design,high mold utilization rate.

Curing process:-"fixed tire film steam curing"is adopted.Three boiler equipment and three lines are respectively laid out with steam pipes,which are connected to the bottom interface of the mold.After concrete pouring,the upper part of the ventilation is covered with tarps to carry out component maintenance.

The PC factory environment

2) Shaanxi Energy Green Building Industrial Park project,which has the highest assembly rate(91.1%)in Northwest China;It is the earliest prefabricated building project in Shaanxi Province that was rated as national AAA level.

① It is the first project under construction in the province and even in the northwest of China to assemble the integral concrete frame structure and fully apply the assembly type decoration,with the highest assembly rate.

According to GBT51129-2017"Prefabricated Building Evaluation Standard":61%of vertical components and 81%of horizontal components are applied.The assembly rate is 91.1%,reaching the national AAA class prefabricated building.

② Toilet USES integrated wei yu, by the integral waterproof at the bottom of the chassis, integrated fast loading wallboard, integrated ceiling and so on industrialization of flexible waterproof chassis whole, whole space that defend bath and components combined with drainage on thin film method, avoiding the advantages of lower noise when drainage, improving the quality of living experience integration design, fit is high.

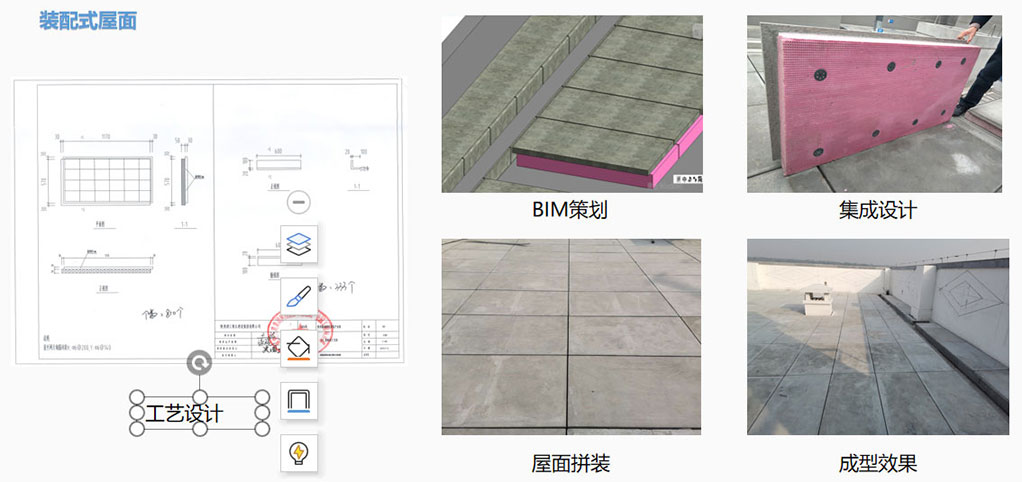

③ According to the roofing construction drawing for PC roofing board layout and design, the roofing process is simplified, the factory integrated processing into production, factory prefabrication molding quality is good. Before the construction, according to the layout drawing, the roof forming effect is beautiful and generous.

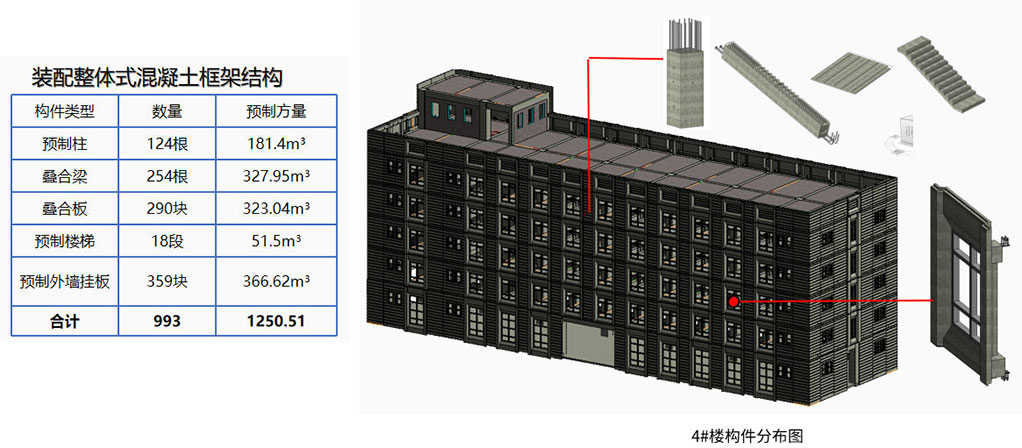

2)Jintai Dongjun Project is the largest residential group project with integrated shear wall currently under construction in Shaanxi Province.

Component distribution and prefabrication rate

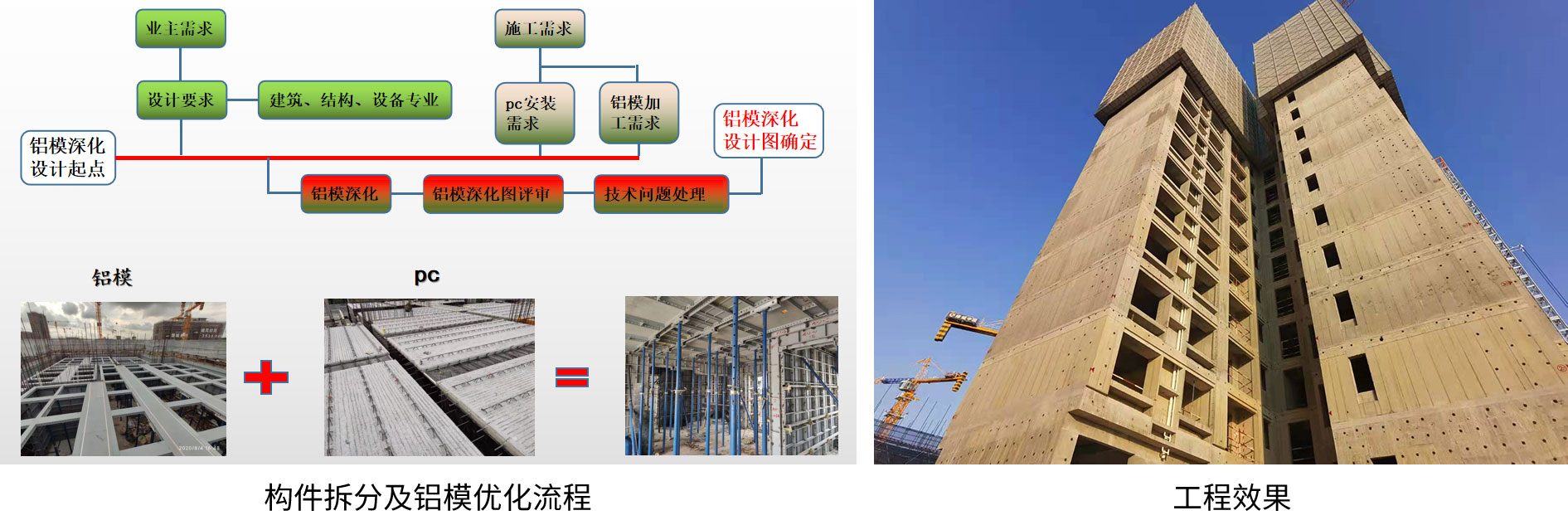

3)The project of Guangzhou • Greentown takes the lead in using the "aluminum mold +PC+ climbing frame" mode for construction.

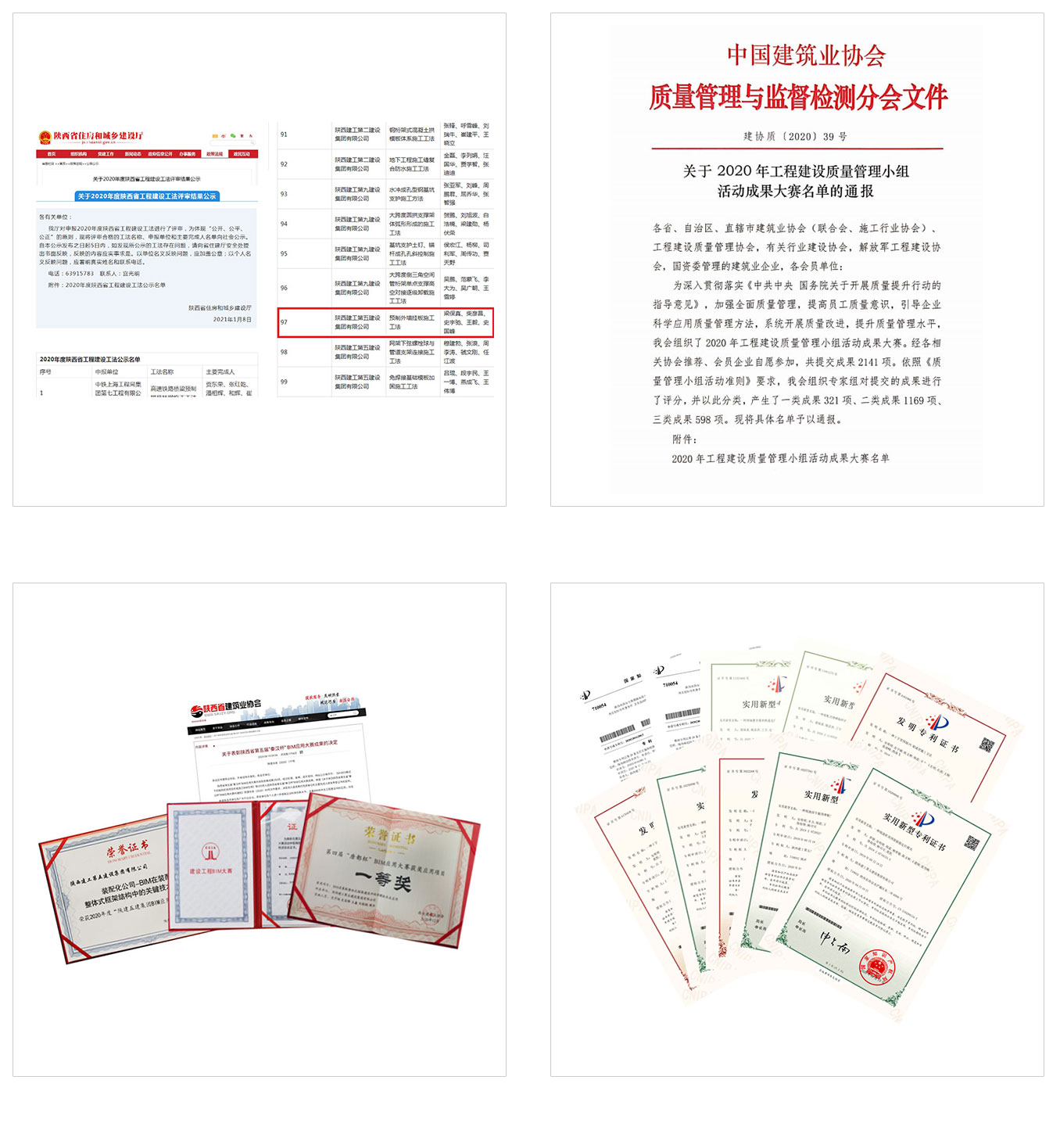

Honor

2 national assembly demonstration projects.

2 provincial assembly type scientific research projects.

1 provincial pilot demonstration project.

Scan the QR code to read on your phone

Address: Kuangshan intersection, East 2nd Ring Road, Xi'an, China (No. 4333, Jinhua North Road)

Zip code: 710032 陕ICP备17011660号 Powered by www.300.cn

Public number

-

Tel

-

E-mail

-

Whatapp

-

Message

-

top